TradeNav

Seamlessly manage multimodal freight shipments

TradeNav is Santova’s cloud-based easy-to-use order management system, providing the latest supply chain management application software exclusively to Santova clients.

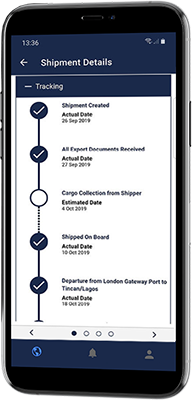

TradeNav assists in unlocking supply chain data, enabling visibility, transparency and accurate real-time tracking functionality. TradeNav is accessible via the Santova App, which offers live shipment tracking and progress alerts, electronic document distribution and live chat support.

New to Santova?

Existing Client?

End-to-end Supply Chain Optimization

Supply chain optimization refers to the process of maximizing the efficiency and effectiveness of a company’s supply chain management in order to reduce costs and improve profitability. The goal of supply chain optimization is to minimize waste, optimize resource utilization, and increase customer satisfaction.

Supply chain optimization requires a thorough understanding of the company’s supply chain structure, as well as the ability to analyze and improve supply chain performance. By optimizing the supply chain, companies can reduce costs, improve efficiency, and increase customer satisfaction, ultimately leading to improved profitability and competitiveness in the marketplace.

Our Supply Chain Services include:

Mapping the Current Supply Chain

The first step in supply chain optimization is to map out the entire supply chain, including all the suppliers, manufacturers, distributors, and retailers involved in the process. This provides a clear picture of how the various elements of the supply chain are interconnected and where potential bottlenecks or inefficiencies may exist.

Analyzing performance

Once the supply chain has been mapped out, the next step is to analyze the performance of each element in the chain. This includes assessing factors such as lead times, inventory levels, production schedules, transportation costs, and customer demand. By identifying areas where performance can be improved, the company can begin to develop strategies to optimize the supply chain.

Identifying opportunities for improvement

Based on the analysis of supply chain performance, the company can identify areas where improvements can be made. This may include optimizing inventory levels, reducing transportation costs, improving production scheduling, or sourcing materials from different suppliers. The company may also explore new technologies or processes that can improve efficiency and reduce waste.

Developing and implementing a plan

Once opportunities for improvement have been identified, the company can develop a plan to implement changes to the supply chain. This may involve reconfiguring the supply chain structure, adopting new technologies, or renegotiating contracts with suppliers or logistics providers. The plan should include specific goals and objectives, as well as a timeline for implementation.